Diamonds a forever

EVER since the first synthetic diamond process - the high-pressure catalytic - was perfected by General Electric i and De Beers in South Africa, the mat found many applications in industry.

EVER since the first synthetic diamond process - the high-pressure catalytic - was perfected by General Electric i and De Beers in South Africa, the mat found many applications in industry.

The remarkable mechanical prop diamond make it ideal for many pt Synthetic diamonds are extensively grinding and cutting tools and in m turing wear-resistant surfaces and evi speaker diaphragms. In the late 1(ft approach called the chemical vapour tion method was developed. This rn chief drawback is that the growth r exceedingly slow. For a good quality d deposit, the best growth rate at optin ditions is roughly one micrometre p This shortcoming has affected the eco use of diamonds. A recent study by P G Partridge, Internal of Medical Science, has rised id an increase in the growth rates of D& by the chemical vapour deposi i6chmique. The technique involves @p a plasma by microwaves and a awbon charge in hydrogen gas, and pmg the diamond on a substrate a usuafly tungsten (Nature, Vol 377, 21, 1995).

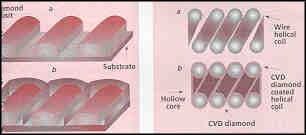

r11w insight provided by Partridge coHeagues has led to the discovery Ki2l deposition on many closely ints, if allowed to grow (side-can increase the effective growth ifold. They have used a small rr tungsten spiral upon which the diamond is deposited. The effective growth rate is increased by the number of turns of the spiral. They have also done detailed calculations to show that a closely spaced grid can be coated simultaneously with a continuous, though not very smooth, sheet of diamond.

The increased growth rates for diamond deposition could bring down the costs substantially and make it economical for various other applications. These include diamond-reinforced, high strength composites for high technology uses. The coming years will defenitely mean large- scale incorporation of chemically deposited diamonds for diverse applications.