A reprieve for the paper industry

JUTE could find exciting new applications as an environmentally friendly raw material in paper-making, contend experts, even though it is being increasingly sidelined by synthetic fibres in the making of Hessian sacks.

JUTE could find exciting new applications as an environmentally friendly raw material in paper-making, contend experts, even though it is being increasingly sidelined by synthetic fibres in the making of Hessian sacks.

Scientists at the Central Pulp and Paper Research Institute (CPPRI) in Saharanpur, have found jute pulp to be almost as good as wood pulp for making paper. Jute possesses all the attributes of quality paper -- long, thick-walled, bulky fibres and low cellulose and lignin (a carbohydrate resistant to compression and tension) content.

Analysts believe that if jute can be developed into a commercially viable raw material for paper-making, it could bail the paper industry out of an accelerating raw material crisis. With increasing demand for paper and decreasing forest resources, paper manufacturers are becoming more and more dependent on imported waste paper and pulp. It is estimated that in 2015, raw material imports will cost the country $2,000 in foreign exchange.

Large-scale possiblities

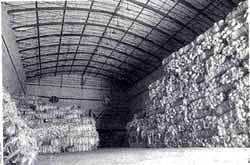

"With an annual production of 1.4 to 2 million tonnes, jute is the only long fibre material available in ample quantity for large-scale use in the paper industry," says L V Saptharishi, national programme manager of the National Jute Development Programme, launched last October by the Union ministry of textiles in collaboration with the United Nations Development Programme (UNDP). Moreover, he explains, unlike wood, jute is an annually renewable resource.

The jute programme aims to increase the use of jute for paper-making from 1 to 6 per cent of total jute production. Several jute experts believe jute is superior to bagasse, which is currently the most extensively used agro-based raw material for making paper. Bagasse fibre is shorter and requires the addition of other long fibres to make quality paper. Moreover, pulping bagasse is very expensive.

Jute received a boost recently when ITC's Calcutta-based Tribeni Tissues Ltd and CPPRI tied up with Germany's Kraftanlaen-Heidelberg to explore ways of using jute as raw material for producing speciality and value-added papers, such as cigarette tissues, diapers and insulation and grease-proof papers. Jute pulp does not have to be bleached with chlorine, which produces the toxic compound dioxin, and hence is likely to find a market in the environmentally-conscious West, says Saptharishi.

A few smaller paper mills such as Madhya Bharat Papers Ltd (MBPL), are also experimenting on making quality writing and printing papers from gunny-cutting wastes. Says T Kathirvelu, senior manager at MBPL, "Using gunny pulp instead of imported pulp can save foreign exchange to the tune of Rs 2,000 per tonne. Also, gunny pulp produces lesser pollution than conventional raw materials because it contains very little lignin."

Though it holds out promise for the paper industry, jute is not without drawbacks. It is not easy to remove contaminants such as bark, dirt and plastics from jute fibres and recycled gunny cutting wastes. Also, pulping technologies are not geared to handle jute. "Nevertheless, new pulping techniques developed abroad can solve many of our problems," says Saptharishi.

There is need for further research to make writing and printing paper from jute, says S L Keswani, paper technologist and managing director of the Delhi-based Chemprojects Design and Engineering Pvt Ltd. CPPRI is already working on a UNDP project to produce newsprint and other varieties of paper from jute. Recently, CPPRI scientists reported that jute sticks, which are normally burnt as domestic fuel, can be pulped to make newsprint. Researchers are also trying to develop alternative pulping, fibre-cleaning and bleaching processes, essential before jute fibre can be pushed into the market.

"As yet it is a bit of a gamble for us," says Vivek Rae, chief of the UNDP jute unit. "If we succeed, it will be nothing short of a miracle. Not only will the paper industry get a reprieve, but the jute farmer could also enjoy an Indian summer."