Beating the grind

RESEARCHERS at the University of Queensland in Australia have developed a chemical process to produce superconductors -- materials that offer no resistance to the flow of current -- in quantities large enough for industrial applications (New Scientist, Vol 142, No 1921).

RESEARCHERS at the University of Queensland in Australia have developed a chemical process to produce superconductors -- materials that offer no resistance to the flow of current -- in quantities large enough for industrial applications (New Scientist, Vol 142, No 1921).

So far, superconductivity has been obtained only in some substances and at extremely low temperatures. Superconductors were made by mixing metallic oxides and grinding them together. The mix was then heated to high temperatures to yield superconducting material. However, only about 10 grams of high-quality superconducting material could be produced at one time using this method because superconductors are highly sensitive to impurities. This quantity was far too little for industrial use.

In the new process, the grinding stage is replaced by a chemical process that is twice as quick. Salts of the metals in solution form are mixed with a salt containing a chemical group called oxalate, which precipitates the superconducting compound. The new process guarantees large amounts of superconducting material of better quality than that produced through the grinding method. Already, 1 kg of superconducting material has been produced in one shot using the new technique.

Since the advent of materials that become superconductors at liquid nitrogen temperature (-196oC) in 1986, several laboratories and companies have shown interest in taking them to the marketplace in the form of wires and rods. Previously, compounds became superconductors at much lower temperatures, for which they had to be cooled by expensive liquid helium.

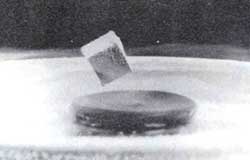

Superconductors could transform many electrical and magnetic applications, ranging from superfast trains through a phenomenon called magnetic levitation to less expensive magnetic resonance imaging diagnostics. These applications require large quantities of superconducting materials and any process that speeds up the large-scale production of these materials could revolutionise the field of electromagnetism.