Bridging gaps

THE rural areas of developing countries disadvantaged in many ways, one rthem being access routes. Heavy and flood conditions completely Mdcte these remote villages when Coa h roads are either washed away mud-swamped.

THE rural areas of developing countries disadvantaged in many ways, one rthem being access routes. Heavy and flood conditions completely Mdcte these remote villages when Coa h roads are either washed away mud-swamped.

Richard Tufnell, International R%C;@nator of the Dry Stone Walling *Avociation of Great Britain has a method which easily mes the problem (Appro- ftpeoTe,hnology, Vol 22, No 1). Tafnell's option requires proper "brPnisation and a little hard work for a short time to build an "Sorroach road which could 'n-andle traffic to and from !11-oftages for many years with minimal maintenance.

The dry stone causeway, as the method is called, is similar to Lb@w-bridge as it serves the same arpose, but - it can be built on the ftomagers' initiative using locally avail- ahk material. This is not only inexpen ; @ut also does not require any engineering skills. About a hundred people required to accomplish the feat in a week's time.

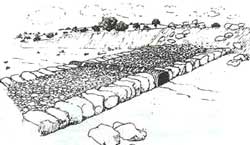

Volunteers are first separated into main groups - 'the stone gatherers the builders. Each group has a er to ensure proper management organisation. The stones are Led ftom nearby fields and should cally be of three sizes. The sides of causeway are made up of large, 11@vy boulders. Stones of sizes ranging Ithat of a football to an orange used for the centre of the causeway. levelling purpose, small-sized nes are required. The total weight all stones collected should be about 150-200 tonnes. The next step Mvolves the marking of the site of the useway. It could be the old track site a new site where the river flows 4rough rocky outcrop or surface, not 1=1kr from the original path. Strings now A causeway sketch: allowing free movement have to be pegged to delineate the causeway area.

The string is held horizontal to a height of 30 cm from the river, on either sides of the bank, by two individuals. Once the first string is pegged to th? ground, seven metres or seven large paces are measured in the direction where the causeway width is to lie. This string is also pegged in the same manner, but extra precaution is to be taken in this case as the two strings have to be at the same level.

The building process begins with a large boulder being placed along the string so that its top reaches the string without actually touching it. The boulder can be pinned into place with the help of small stones which are wedged in the available gaps. Similarly, another boulder is placed close to the first one, making sure that the two are touching each other and the gaps again filled up by wedging stones in between. This is done till a gap of 1-1.5m remains in the centre. This gap is used for laying the drainage pipeline.

The pipeline is placed in the centre of the stream to deal with low volumes of water and prevent silting of the causeway. Some 13-14 corrugated metal half sections of diameter 60-70cm. are placed in the middle of this drain. Each section overlaps the one in front by some 20cm. This helps to lock them together. Once the drain is laid, the layer is completed by placing boulders to lock the drain in place and the centre of the causeway is filled up with stones. These should reach the height of the boulders, but not above it, forming an even level layer. The strings are again raised by another 30cm over the boulders to form the second layer. The same procedure is followed with the exception that the upper boulder should rest on two lower ones. This is known as 'breaking the joints'. The procedure is once again repeated to form the third layer.

The final layering is done using small stones and chippings to bind the gaps and to give the causeway a smooth appearance. Maintaining the causeway involves annual repairs which must be carried out each year before the monsoon season.

Related Content

- Financing adaptation in India

- Affidavit filed by Arunachal Pradesh regarding compliance of MSW Rules 2016 and other environmental issues, 03/02/2024

- Mainstreaming financial aggregation for distributed renewable energy

- Transforming India’s approach to cancer care

- Just energy transition: economic implications for Jharkhand

- State of finance for nature 2023