Measuring defects

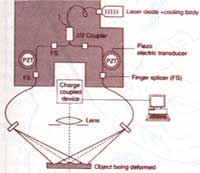

A TEAM of scientists, led by R S Sirohi, at the Indian Institute of Technology, Madras, has developed a video halographic system which they say will provide a convenient way of quantifying the deformation of components in a non- destructive way and can be used in varied fields like space research, optical metrology, biomedicine and engineering of machine components. The system is based on fibre optics and has quite a few advantages over conventiona! halography.

A TEAM of scientists, led by R S Sirohi, at the Indian Institute of Technology, Madras, has developed a video halographic system which they say will provide a convenient way of quantifying the deformation of components in a non- destructive way and can be used in varied fields like space research, optical metrology, biomedicine and engineering of machine components. The system is based on fibre optics and has quite a few advantages over conventiona! halography.

Conventional halography is time consuming as one has to record the images on photo graphic plates, develop and fix them and it also requires a dark room and a costly vibration isolation table. But using video halo-graphy, technically known as electronic speckle pattern interferometre, the object can be studied under illuminated conditions at a rate of 25 frames per second. The team studied the deformation of a fibre reinforced plastic plate using their system.

The defects on the object show as kinks in the speckle pattern. Industries are increasingly using optical testing systems to study the modes of vibration, deformation and sources of noise in engine components and tyres. "Even a whole car body can be studied in detail," said Sirohi.

Related Content

- Order of the National Green Tribunal regarding pollution by industrial establishments in Sundargarh mainly iron and steel industries, Odisha, 22/11/2023

- Order of the High Court of Orissa regarding death of a young girl in the premises of the school due to negligence of the authorities, Odisha, 11/08/2022

- DPCC report to the NGT on the running of the Poultry Market and M/s Delhi Food Processing Complex, Ghazipur, Uttar Pradesh, 29/04/2022

- Order of the National Green Tribunal regarding authorization granted to a waste facility at village Juna Deesa, Banas Kantha District, Gujarat, 01/10/2019

- Order of the National Green Tribunal regarding illegal discharge of untreated effluents by Nityanand Institute of Medical Science, Pune, Maharashtra, 04/07/2019

- Order of the High Court of Delhi ban on junk food and carbonated drinks in schools, 25/02/2015