Working out

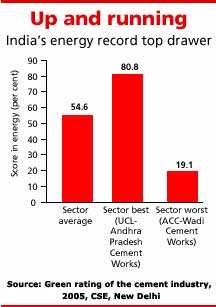

Making cement is energy-intensive. Energy accounts for a significant portion of the cost of producing cement. Most technological advancement, unsurprisingly, has been directed towards reducing its consumption. Unlike other industries in India, in which technological levels lag behind the best in the world, the cement industry is state of the art. This is the key to the Indian cement sector's competitiveness. It also makes this sector one of the most energy-efficient (see graph: Energy drive).

Making cement is energy-intensive. Energy accounts for a significant portion of the cost of producing cement. Most technological advancement, unsurprisingly, has been directed towards reducing its consumption. Unlike other industries in India, in which technological levels lag behind the best in the world, the cement industry is state of the art. This is the key to the Indian cement sector's competitiveness. It also makes this sector one of the most energy-efficient (see graph: Energy drive).

About 80 per cent of energy consumed by a cement plant happens in the clinkerisation process. The sector is quite efficient in utilising energy in the kiln. It is amongst the lowest compared to other cement manufacturers (see table: Global edge). Japan scores due to its advanced technology while countries like China and the us are the laggards, using obsolete technology.

Despite its decent performance, The cement industry can improve energy consumption by 25 per cent more than the best achievable figure of 2.65 gigajoule/tonne of clinker.

Not only is the industry thermal energy efficient, it has also managed to lower power consumption. Power in the cement plant is required for all the grinding sections

Related Content

- First food: business of taste

- Order of the National Green Tribunal regarding large scale felling of toddy yielding palm trees in Bihar, 05/06/2025

- Order of the National Green Tribunal regarding waste disposal in Ghazipur drain, Delhi, 28/05/2025

- Order of the National Green Tribunal on the demarcation of Nahargarh Wildlife Sanctuary, Jaipur, Rajasthan, 27/05/2025

- Order of the National Green Tribunal regarding restoration of Suka Paika canal, Cuttack, Odisha, 15/05/2025

- Reply by the Central Pollution Control Board (CPCB) on cutting of trees for the construction of a cold storage project, Vikasnagar, Uttarakhand, 09/05/2025