The liquid heat trap

THIS is a pond with a difference -- a lifeless, bitter-with-salt body of water that gets hotter as you go deeper and is scalding at the bottom. But for the Kutch dairy in Bhuj, Gujarat, the 6,000 sq metre pond is a gargantuan trap for solar energy and heats about 80,000 litres of water a day.

THIS is a pond with a difference -- a lifeless, bitter-with-salt body of water that gets hotter as you go deeper and is scalding at the bottom. But for the Kutch dairy in Bhuj, Gujarat, the 6,000 sq metre pond is a gargantuan trap for solar energy and heats about 80,000 litres of water a day.

Called, simply, a solar pond, this storehouse of the sun's thermal energy is the largest of its kind in the world. It became operational in September 1993, and now provides water heated to between 70 and 80 degrees Celsius for use in boilers and for cleaning and washing.

Experts say a solar pond has 3 major advantages over other solar technologies -- a low cost-per-unit of collecting area with an inbuilt, large storage capacity; a huge surface area allowing the concentration of diffuse solar radiation on a large-scale; and, by trapping heat and storing it for a month, it can even supply energy during the monsoons and no-sunshine periods.

Research and demonstration

Essentially a research and demonstration project, work on the pond was started in 1987 as a collaborative effort between the Gujarat Energy Development Agency (GEDA), the Delhi-based Tata Energy Research Institute and the Gujarat Dairy Development Corporation Ltd. Financed by the ministry of non-conventional energy sources, the project had a total outlay of Rs 87.3 lakh.

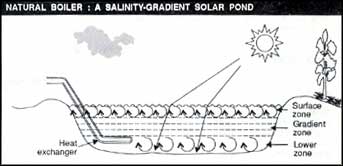

The solar pond works by checking the tendency of water to lose heat by convection -- a physical process that entails the rising of warm liquid to the top of a repository and losing heat to the atmosphere. In a solar pond, however, the tendency of water to lose heat thus is inhibited by adding common salt to the bottom layer and rendering it too dense to ascend.

The pond at Bhuj is 3.5 metres deep with the top layer -- which obviously remains at atmospheric temperature -- being minimally saline. Then comes the gradient zone, where the salt content increases in proportion to depth, creating a "salinity gradient". The density of the bottom layer, at about 1,190 kg per cum -- is the highest. The stable gradient zone acts as a transparent heat insulator, keeping the heat trapped in the bottom. It takes about a month to raise the temperature of the bottom layer to above 70 degree Celsius. Then the heat can be withdrawn daily by pumping the hot brine through a chamber surrounded with fresh water.

A total of 4,000 tonnes of salt is dissolved in the pond; its natural diffusion throughout the water mass is checked by constantly monitoring the density at various levels. Says GEDA deputy-director (technical) M M Pandey, "We have developed a computer programme that tells us exactly what quantity of water with how much salt has to be pumped in, and at what level to maintain the exact salinity gradient." The salt is dissolved in an adjacent pond and injected in the low salinity zones of the main pond. Plastic nets one metre wide are installed every 10 metres to suppress wave formations and calcium sulphate is added to prevent the development of algae.

The thermal energy generated, says Pandey, can also be used for other purposes such as water desalination. The annual cost of thermal energy for water heating works out to just 33 paise per kilo Watt hour (kWh). This compares more than favourably with solar hot water systems, which cost Rs 1.50 per kWh, says Pandey.

He adds, "This is the first project in our country to successfully demonstrate the use of solar pond technology to deliver industrial process heat." Already, certain industries, Tata Chemicals among them, have shown interest in the pond. And while such large, land consuming solar technologies might not be viable in cities where real estate is at a premium, the project augurs well for the country's vast open spaces.